Inventory management

COVID-19, End of Brexit transition, Christmas, Black Friday, Cyber Monday, these are just a few of the many reasons to stockpile inventory, but what do you do when you have too much or too little of it?

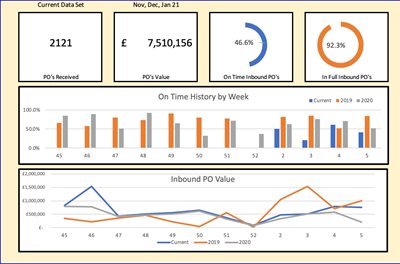

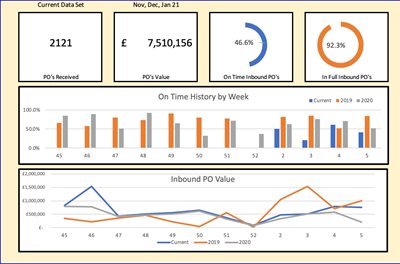

We all know about Min-Max levels, minimum order quantities, lead times and other factors that drive inventory levels, but at Logistics UK we have been able to take these basic principles and convert them into accurate, relevant, targeted KPIs, dashboards and deliverable savings for our customers.

Our approach

Using two to three years’ receipts history we are able to develop analytics tools that consider each product and supplier, in particular the suppliers’ performance against their promised lead times. Combined with the sales history our tools identify ‘ideal’ stock levels for each month of the year, whilst taking into account the seasonality that all business, product groups and product lines experience.

Sales, receipts and inventory analytics and indicators can then be used in tandem to drive out excess stocks, highlight over-buying and target reductions, without having an adverse impact on your own On Time in Full performance.

Outcomes

Excess inventory ties up much needed cash in any business, but often forgotten is the impact on warehousing. Higher storage costs and unnecessarily excessive walk distances for warehouse operatives, tend to add to the day-to-day operating costs. The benefits of better inventory management are much more than just the cash saving, true warehouse optimisation will always consider what is stored as well as how it is stored and handled!

To organise a free discussion with one of our consultants, please get in touch with the team:

Get in touch