🕒 Article read time: 2 minutes

Super swift gates which automatically close off lanes to be trialled on A3

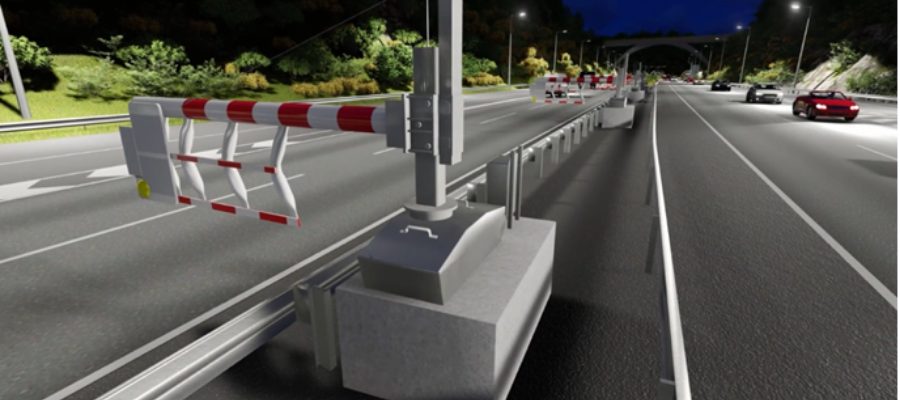

National Highways (formerly Highways England) is trialling an innovative taper system called SwiftGate, which will be able to close off live lanes in just five minutes.

This will save road workers from having to put out cones in the face of often fast-moving oncoming traffic – a process that normally takes around 25 minutes.

SITED AT UK’S LONGEST ROAD TUNNEL

SwiftGate is being installed at the A3 Hindhead Tunnel in Surrey. At 1.2 miles, Hindhead is the longest under-land road tunnel in the UK and frequently needs to be closed for essential maintenance work. To enable maintenance to be carried out safely, workers cone off the entrance on the north and southbound carriageways.

There were 14 vehicle incursions into these roadworks during 2019, placing the lives of road workers at risk.

Now National Highways has teamed up with Kier and Highway Care to trial the automated taper gates which will be installed on the north and southbound carriageways of the tunnel.

FILTERING TRAFFIC OUT SAFELY

The gates clearly and safely filter traffic out of the traffic lane. Cones can then be put out beyond the taper to clearly mark out the closed-off lane.

As well as avoiding the need for workers to manually set out tapers, the arms are a strong visual deterrent which will help avoid incursions, particularly at night-time.

“Installing and removing a taper of cones in the face of traffic exposes our road workers to risk, particularly on elevated sections of road, bridges or tunnels where there may not be an embankment or place of safety,” said Martin Bolt, Head of Lean and Continuous Improvement, National Highways, “If successful, SwiftGate is another step to zero live lane working for our workforce as we work towards our goal of ensuring nobody is harmed while working or travelling on our roads.

“The automated tapers free up workers to do other jobs and can be put out in just 50 seconds meaning work can begin straight away with less disruption for road users. We look forward to seeing SwiftGate in action at Hindhead Tunnel.”

MODERNISING APPROACH TO ROAD WORKER PROTECTION

Mark Sheppard, Kier Highways Senior Project Manager, said: “The SwiftGate project will give us a great opportunity to trial something that is completely new to the National Highways network, that will modernise the standard approach to road worker protection.

“Traffic management installation can be a high-risk activity, so the opportunity to introduce an automatic solution that has the potential to remove the need to put our workforce in the ‘firing-line’, is a worthy project.”

IMPROVING STAFF SAFETY AND CUSTOMER JOURNEYS

Ben Duncker, Highway Care Business Development Director, said: “We are very pleased, after many months of hard work from the project team, that we are able to commence the trial of this exciting, safety innovation working collaboratively with Kier and National Highways.

“We are confident that the system will be a success in not only improving the safety of our traffic management operatives but also improving customer journeys through the faster and more efficient closing and reopening of lanes.

“Safety through innovation is our priority and the ability to trial such new solutions with National Highways is a testament to their commitment to making the roads safer for all users.”

AUTOMATED CONE LAYING MACHINE

SwiftGate follows the successful trials of an automated cone laying machine by National Highways, Highway Care and Kier. The Falcon ACLM vehicle puts out and retrieves cones, avoiding the need for a two-man team to lift and drop cones from the back of a moving vehicle.

A second automated cone laying machine being developed by King Highway Products through the National Highways’ innovation fund is due to undergo further off-road testing shortly.

National Highways has a ring-fenced pot, the Innovation and Modernisation Fund, which is helping to maximise the opportunities offered by technologies such as automated vehicles.

It is part of National Highways’ Digital Roads 2025 vision which will fundamentally change how our roads are designed, built, operated and used. The strategy sets out how the growth of digital technology and the move to electric, connected and autonomous vehicles will create the roads of the future.

James Firth, Head of Road Freight Regulation Policy, Logistics UK, said: “In a safety-critical sector like logistics, the safety of drivers and other road users is of paramount importance. We congratulate National Highways on its adoption of this innovative technology, which promises to not only improve the safety of both road workers and road users but give commercial drivers greater certainty over their journey time too.”

*www.logistics.org.uk/road

Published On: 13/01/2022 16:00:43

Comments Section

If you are a Logistics UK member login to add comments.