🕒 Article read time: 2 minutes

Logistics UK impressed by progress of Siemens’ new ehighway trials in Germany

While the UK is waiting for the government to progress the Zero Emission Road Freight demonstrators (ZERFT) to help identify a suitable zero-tailpipe carbon emission solution for large HGVs, the German government is focussing on a funded and structured approach to testing static charging, ehighway and hydrogen solutions.

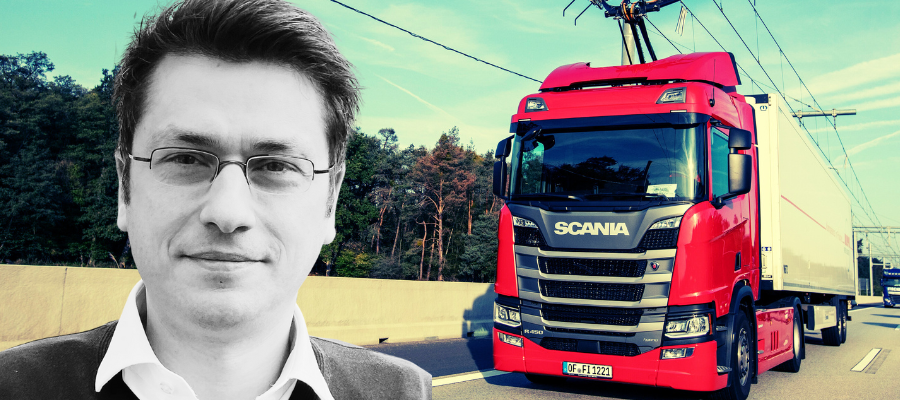

“As part of the country's solution to decarbonisation,” explains Ben Garrett, Deputy Director of Public Affairs at Logistics UK, “Siemens has delivered three test ehighway tracks in Germany, including one on 5km of autobahn between Lubeck and the port of Hamburg – specifically above a single lane of this autobahn in each direction on which test runs for new vehicles can be made.

“Scania-modified electric battery-diesel hybrid lorries, operated by logistics company Bode, are under test on these tracks, drawing electric charge from overhead electric wires. These wires, via a pantograph, power the trucks while they drive beneath them and give their batteries charge for a few more km.”

EHIGHWAYS v ELECTRIFICATION

As well as testing how the system works for the HGVs, including for day-to-day management, the effect on the local energy grid is also being researched.

According to Siemens, there are some interesting differences between this test solution and the rail electrification that inspired it:

- Rail overhead cables provide the positive charge, with the neutral delivered by the contact between a train’s steel wheels on steel tracks. As HGVs have rubber wheels, two overhead lines are required for the positive and neutral.

- Much more moisture is kicked up from the road into the air than from trains into the air, owing to the larger surface area of a road and the effect of tyres on it. As a result, the system has been designed to cope with more moisture upon it.

- In addition, with HGVs operating at higher frequencies than trains, the overhead cables are more robust: thicker and strung more tightly. There are also shorter gaps between cable droppers so that if any cable is damaged, it won’t hang loose into the traffic area.

- Unlike trains, HGVs do not run on tracks, meaning drivers need to actively stay within their lane to maintain contact between the pantograph and the wires.

THREE AND EASY

“The German government is seeking to be neutral on the options of static charging, ehighways and hydrogen, but is exploring all three,” continues Garrett. “This includes providing funding for test vehicles and infrastructure, helping to navigate regulations, establishing innovation clusters and supporting industry and stakeholder engagement around test projects.”

According to Britta Somner, of the VDI VDE IT project management agency acting on behalf of the German government, while diesel works for all types of road logistics vehicle performing all tasks, finding zero carbon approaches requires a different approach: using different technologies for different situations, with all requiring energy infrastructure.

As such, there is a growing understanding that the answer for zero emission HGVs is likely a mix of technologies. This could see ehighways used for highly intensive stretches of road, supported by static charging, and hydrogen for more specialist or bespoke operations, as hydrogen is expensive and is likely to be needed for heavy industry.

“It’s also important,” explains Garrett, “that whatever new systems and infrastructure are ultimately put in place, there is coordination across Europe to support HGVs operating across the continent.”

*www.logistics.org.uk/campaigns/better-infrastructure

Published On: 04/05/2023 16:00:00

Comments Section

If you are a Logistics UK member login to add comments.